News

July 29, 2025

Read More

How to Select the Right Overhead Crane System for Your Business?

April 8, 2025

Read More

Three Generations of Success: The Street Crane Legacy

March 31, 2025

Read More

Street Crane Unveils New Website

March 31, 2025

Read More

New Engineering Manager Appointed

The company required bespoke overhead cranes to significantly improve order turnaround, so turned to Street Crane for the solution.

September 9, 2024

Read More

75 Years and counting

May 10, 2021

Read More

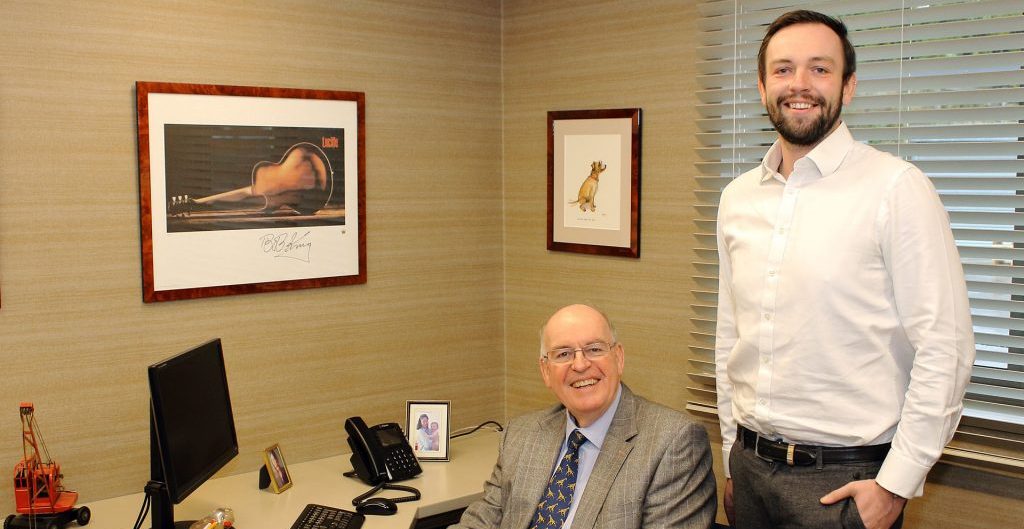

Street Crane welcomes grandson of founder

November 13, 2020

Read More

Steel & Alloy drives ahead with Street Crane

June 26, 2020

Read More

Street Crane accredited to JOSCAR level 2

January 10, 2019

Read More