LATEST NEWS

Tata’s steel distribution centre at Redcar has invested in special cranes from Street Crane Company to improve order turnaround. The Teeside depot refit includes the installation of four 12 tonne SWL overhead travelling cranes of a radically different design that will significantly improve material processing and speed of delivery to customers.

Redcar is one of 49 Tata Steel Service Centres nationwide that provide locally accessible steel stock with added value processing to client requirements. Plate and sections for use in engineering and marine fabrications or structural steelwork can be cut, shot blasted and painted prior to delivery to customers ready for the next stage of manufacture.

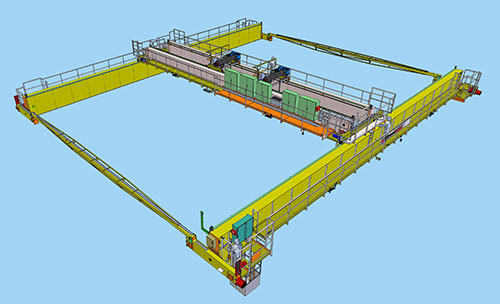

Street Crane’s sales director, Chris Lindley-Smith, explained, “The high rates of material flow and particular processing needs demanded a more innovative crane configuration. Four cranes have been provided of double bridge design, where two linked beams span the 20 metre bays and on these is fitted a 27 metre crane bridge, bearing twin six tonne hoists. This permits zoned north/south and east/west material flow allowing steel to be brought into the processing bay, with transfer through the shot blast and painting processes before the finished steel is shipped out to customers.”

The twin six tonne hoists on each crane can be operated singly or in tandem for heavier or awkwardly shaped loads giving additional stability. All hoists have magnet lifting from Walker Magnetics. Anti-collision systems permit safe crane movement on a common gantry with audible alarms and amber flashing lights to warn of the other crane approach. Twin floodlights on each crane are operated from the remote controller.

Minimising maintenance downtime is vital for maximum productivity. Hours of service metering on all crane motions will assist in planning proactive maintenance to sustain the plants uptime and efficiency.

Crane control will be by push button infra-red link to comply with Tata requirements. Other key safety features include taut-wire safety lines to crane bridge platforms and ten safety harness anchor points at key locations such as panels, crabs and end carriages.